|

Download the Diatome

Diamond Knives brochure:

ENG ENG

DEU DEU

FRA FRA

ultra sonic Maxi Flyer:

ENG ENG

CEMOVIS Flyer:

ENG ENG

ultra semi case study:

ENG ENG

cryo immuno case study:

ENG ENG

Perfect Loop flyer:

ENG ENG

|

|

|

|

|

ultra sonic

| • |

Thinner sections |

| • |

No compression |

| • |

Best structure preservation |

The patented ultra sonic knife allows

the cutting of ultrathin sections free of

compression (D. Studer et al., Journal

of Microscopy, Vol. 197, pp. 94 – 100,

2000).

With correct setting of frequency and

amplitude the sections become as long

as the height of the sample.

Best results are not only achieved with

biological samples, but also with polymers (J. S. Vastenhout et al., Microscopy

and Microanalysis 8, 2001. J. S. Vastenhout et al., Microscopy Today, pp. 20 – 21,

2006).

We have tested the ultra sonic knife with

the following samples:

| • |

Biological samples in Epon, Araldite, EM Bed, etc. |

| • |

Biological samples in acrylic resins (Lowicryl, LR White). |

| • |

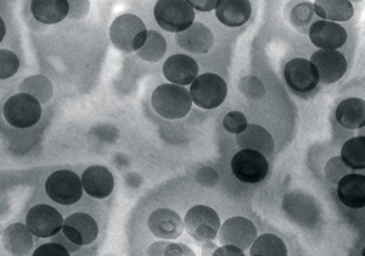

Rigid polymers such as PS, PMMA, ABS, HIPS, modified PP, blends of various kind |

|

|

|

Polycarbonate modified with rubber Jens Sicking, Bayer Technology Services, Leverkusen.

|

|

|

|

|